Operations Healthcare Jan 3, 2019

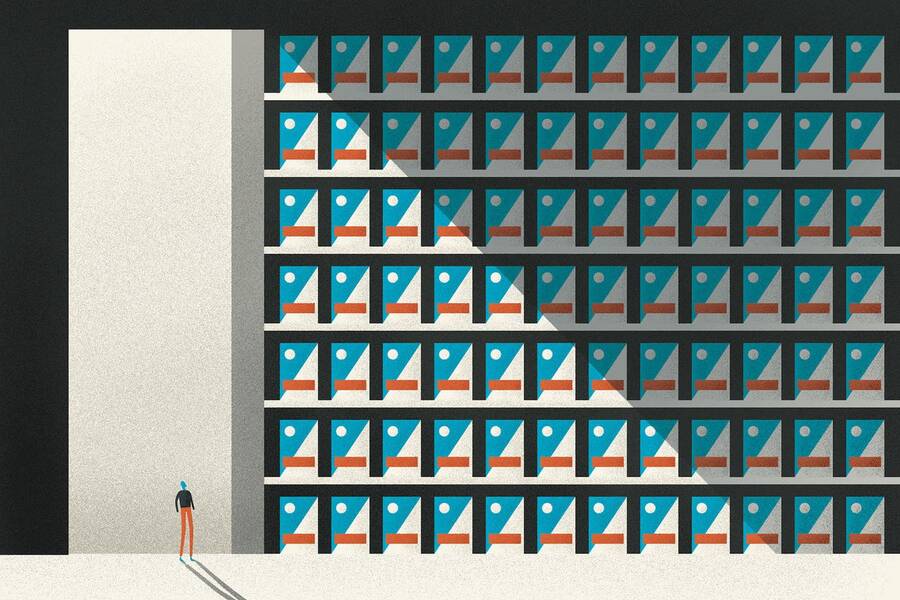

There’s a Better Way to Manage Your Inventory

Using data from a drug-store chain, a new model finds opportunities to prevent shortages and boost profits.

If your local drugstore is out of the prescription antibiotic you need, you’ll likely be frustrated and head to another pharmacy.

But for the stores themselves, the stakes of such inventory issues can go well beyond frustration: overstocking can waste money and valuable shelf space, while understocking specific products can mean not only diminished profits but also potential penalties from regulators.

So pharmacy retailers are keen to optimize their inventory-management systems, as Chaithanya Bandi, associate professor of operations at the Kellogg School, observed firsthand in a recent study.

“We worked with one of the largest pharmacy retailers in India to understand how they could optimize inventory management across multiple locations and minimize the costs involved,” Bandi says. He conducted the research with collaborators Eojin Han and Omid Nohadani, both of Northwestern’s McCormick School of Engineering.

The model they developed improves on standard inventory-management systems and policies used by many large businesses in several ways, Bandi explains. It helps to eliminate gaps in inventory monitoring, better predict demand across all products, and treat stores as part of a network rather than standalone entities.

The research shows that incorporating new strategic features into an inventory-management system can improve a pharmacy’s profits by as much as 17%. What’s more, the same inventory-management approach can be implemented in industries well beyond retail pharmacy, such as other consumer goods and technology.

“There remains a large gap between what’s state-of-the-art in inventory management and what companies today do,” Bandi says.

The High Stakes of Pharmacy Inventory Management

The company the researchers studied is one of India’s largest online pharmacy retailers, carrying over 160 brands. The business, which also sells drugs through brick-and-mortar stores, often struggles to predict changes in demand over time.

As such, the retailer has sometimes incurred high penalties for “stocking out,” or running out of a particular pharmaceutical product that customers cannot go without. “These are important products such that even if the retailer runs out, they need to have it on hand within a day or two,” Bandi says.

“There remains a large gap between what’s state-of-the-art in inventory management and what companies today do.”

Customers who are unable to get the prescription they need from a pharmacy can file a report with Indian regulatory agencies. “If a certain number of such reports are made in a year,” Bandi says, “that results in economic punishment” in the form of fines. (While Bandi’s research was based in India, some U.S. states impose similar penalties on pharmaceutical retailers who undersupply drugs.)

But in trying to avoid stock-outs, retailers may take an overly conservative approach: “They simply stock too much product,” Bandi says—and that carries its own costs, including the need for more storage space and potentially unsold inventory.

So Bandi wanted to help the retailer understand how to walk the fine line between under- and overstocking.

Beyond Base-Stock Policies

Many systems of inventory management used what the retail industry calls “base stock” policies: when inventory of a given product (say flu vaccines) falls below a certain level, it triggers an order for more stock, to keep inventory at a base level.

The problem with this system is that a pharmacy can spend days or weeks with the product out of stock, while they wait for the order to be processed and delivered. Alternatively, they may end up with excess inventory if demand drops after the order arrives.

The researchers wanted to create a more dynamic, cost-effective inventory-management system. “Rather than waiting until inventory of a given product falls below a certain amount, they can order more strategically using demand prediction, which the model also incorporates.”

For example, even if inventory of prescription seasonal-allergy medications seemed sufficient based on sales in past years, a retailer could order more of the product if they anticipate a jump in demand due to expected weather patterns, such as drought or unusually high pollen count.

The researchers also incorporated correlations between demand levels for specific products—between cold and cough medicines, for example. According to Bandi, many current systems “simply track item-specific inventory and reorder every time. So exploiting this correlation information would lead to a lot of benefit.”

Another component of smarter inventory management, according to Bandi, is location.

“The company had so many retail locations close to each other,” he says. “But they were treating every particular location as a separate entity, which meant they were overstocking everywhere.”

To address this, the researchers treated retail locations not as standalone stores but as a network that could share inventory. For example, Bandi says, one store may have dozens of flu vaccines in-stock, “but a nearby location is running out. They could quickly transfer the product between locations to optimize inventory. But if you’re looking at locations separately, you’re much more likely to panic and overstock.”

Smarter Inventory Management for All

Bandi and coauthors incorporated data from the Indian pharmaceutical retailer to see how their model performed, studying over 1.5 million transactions on 228 different products over a 40-day period.

The researchers estimated that using an optimized inventory-management system would improve the retailer’s profits by as much as 17%.

That suggests U.S. retail pharmacies like Walgreens and CVS also have much to gain from implementing the new inventory-management strategies. And Bandi believes the advantages of smart inventory management could extend well beyond the retail pharmacy businesses.

He points to a recent McKinsey article exploring how companies in sectors like technology and consumer goods have used more effective approaches to inventory to unlock millions in cash flow and reduce processing time dramatically, with a sizable impact on their bottom line.