Operations Aug 5, 2020

From PPE to Denim and Beer, Here’s What the Pandemic Is Teaching Us about Supply Chains

Five lessons from Kellogg Professor Marty Lariviere.

Riley Mann

The coronavirus crisis has given organizations a lot to think about.

At the award-winning blog, The Operations Room, Marty Lariviere, an operations professor at the Kellogg School, has been posting about the many ways organizations are adapting their supply chains to keep their operations running. He’s also drawing lessons from their efforts.

Here are some of our favorite lessons from the last few months.

What N95 Shortages Say about the Efficiency–Resiliency Trade-off

In the early weeks after the pandemic’s arrival in the U.S., the nation was hit with critical shortages of PPE, including N95 masks. While the spike in demand can account for the shortage to an extent, Lariviere writes that a more complicated set of factors led to the inventory shortfall, including hospitals cutting inventory, manufacturers keeping production lean, and federal government limiting its stockpile of masks and other materials.

In short, all parties involved favored just-in-time efficiency over resiliency.

“Since hospital networks compete with each other for contracts with insurers, the one that doesn’t try to save every dime is going to be at a disadvantage,” Lariviere writes. “A similar logic applies for distributors and producers. An N95 mask is fundamentally a commodity. A given buyer [has] every reason to favor the cheapest option.”

In the short term, as the pandemic continues to strain supply chains, and states see new outbreaks, keeping operations lean will likely take a back seat to staying well stocked. But the long-term future of stockpiling PPE remains murky.

“It is reasonable to expect that if shortages clear up at some point, various players will carry extra inventory for a while,” he writes. “But it’s not clear how long that discipline will last.”

Which leads to the role the federal government could play. As the party with an interest in the nation’s long-term pandemic responsiveness, “they are the ones that could drive some degree of coordination in the supply chain,” he writes.

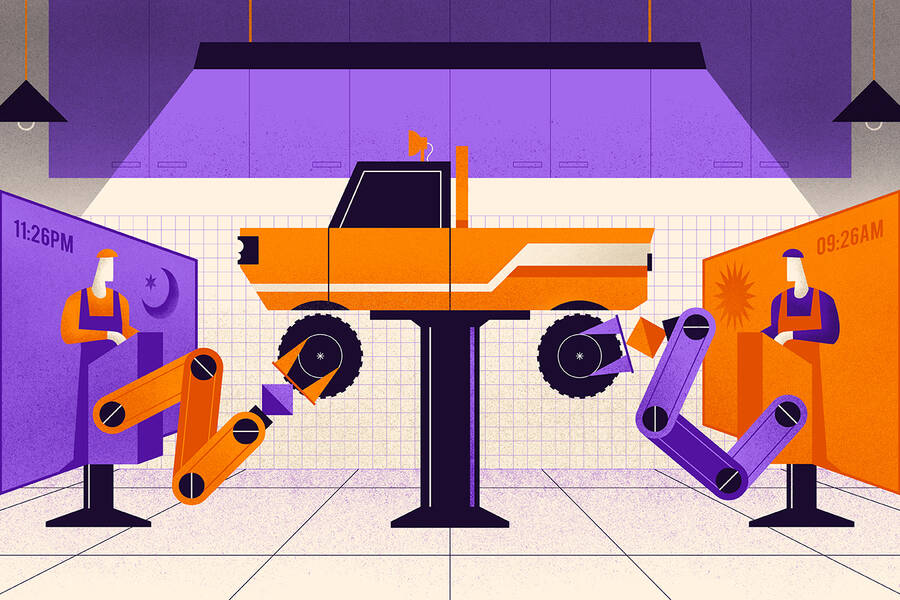

Just-in-Time Supply Chains May Still Have a Role to Play

It’s not just PPE shortages that are revealing the downsides of just-in-time manufacturing. In the wake of the pandemic, experts are now arguing that all kinds of companies have a responsibility to gird their supply chains against risks.

Lariviere isn’t so sure. He is sympathetic to a more tailored approach, using the auto industry as an example of a supply chain that likely won’t transform, and the food industry as one that may need an overhaul.

“It is reasonable to expect that if [PPE] shortages clear up at some point, various players will carry extra inventory for a while. But it’s not clear how long that discipline will last.”

— Marty Lariviere

“Having complicated [car] parts manufactured in multiple locations sacrifices economies of scale and adds complexity for the life of the model,” he writes. “What benefit is there in having that diversification if in fact you have a worldwide catastrophe? As disease spreads, disruption eventually spreads as well.”

The meat industry, on the other hand—with local imputs and unwavering demand—is more likely to change in order to make itself more pandemic-proof.

People Aren’t Buying Jeans, or How Shutdowns Ripple through Supply Chains

When countries around the world went into lockdown in the spring, many of us were not in the mood to shop for clothes, even online. As a result, clothing brands cancelled billions of dollars in orders from their global manufacturers, leaving those suppliers in the lurch.

One Bangladeshi denim factory, for instance, has had to contend with a sudden collapse in demand, despite having completed assembly on some jeans and purchased raw materials up front for others.

“This is fundamentally about how risk gets allocated in a supply chain,” Lariviere writes. “In normal times, the suppliers are fronting money to get materials. For that they have to take on debt.” But those same companies have nowhere to turn with product that has been produced for orders that have been cancelled.

He describes this as a fundamental asymmetry, which advantages the Western brands over their suppliers. Lariviere views this asymmetry as a byproduct of the perception that assembly is not hard to replicate.

“Sewing capacity is just too much a commodity,” he writes. “Brands assume that they can always find someone else equally competent, so there is no reason to not drive the hardest bargain possible.… Implicit in that is that there is little value in having a long-term relationship with any one supplier.”

Fast-Fashion Supply Chains: Too Good to Be True?

Speaking of fashion: For companies like British firm Boohoo, which specializes in crazy fast product launches, the lockdown offered an opportunity to quickly pivot to loungewear. It was able to do so because it had previously shifted production to local mini-factories in the East Midlands city of Leicester.

Boohoo could have been viewed as a success story of a retailer that found a new lane in the crisis.

One problem, though. Those mini-factories were exploiting garment workers, paying them well below living wage and not offering safe working conditions.

“As if abusive labor practices weren’t bad enough, Leicester is currently under lockdown orders as the rest of the country is reopening because the virus is not under control in the city,” Lariviere writes. “This has been tied to the garment industry and Boohoo in particular.”

Boohoo, notes Lariviere, is essentially entangled by its own trade-offs among cost, flexibility, and ethics.

“It’s hard to do as cheaply as Boohoo needs it to be done given their price point. Hard, that is, if they play by the rules,” he writes. “So what is the takeaway here? It might simply be that if it seems too good to be true, it probably is.”

How to Get Rid of Beer When the Bars Are Closed

The pandemic has hit the craft beer industry pretty hard. Many bars and tap rooms where these craft beer brands build customer loyalty one pint at a time have closed. And in stores, customers are sacrificing taste for price and convenience, choosing the less expensive industrial beers that groceries carry in greater quantities.

These challenges are dire. But the pandemic is also revealing weaknesses in the beer industry’s “reverse logistics” system for reusing materials.

For one, what happens to all the kegs (which the brewers own) that are stuck at now-shuttered bars? Locating them is part of the puzzle. “There are 20 million kegs in America, and historically brewers didn’t have a really tight grip on where they were,” Laviriere explains.

Not to mention, what happens to all the beer in those kegs? Who is responsible for picking up the tab on all this stale beer months later?

“You can’t just pour it down the drain, and the industry’s reverse logistics system isn’t really set up to schlepp full kegs home,” Lariviere writes.

*

Read more posts at The Operations Room here.